"What is (PEB) Pre Engineered Building" Learning for Beginner

PEB - Pre Engineered Building

What is Pre Engineered Building?

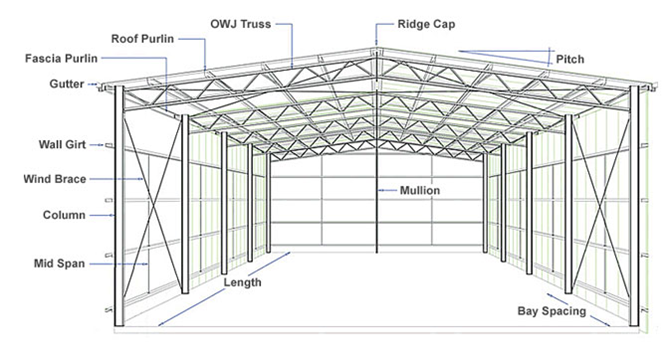

• Pre Engineered Buildings (PEB) are the buildings which

are engineered at a factory and assembled at site.

Components of PEB:

1) Primary Members: - Columns, Rafter, Beams,

Bracings. Members are fabricated by MS Material in I Sections.

2) Secondary Member’s: It is actually Cold Formed

Members, which can be in diff. shapes like “Z”, “C” etc. In general known as

“Purlins”.

3) Roof & Wall Sheet :- Rolled form PPGL ( Pre

Printed Galvanized IRON) material.

4) Accessories :- louvers,

Turbo vent, Skylight, wall light, Puff Panel.

Design Methodology

1.AISC ( American Institute of structural Construction )

3. MBMA ( Metal Building Manufacturing Association )

Important Parameters Require for Design building

- Dimension

of the building = Length, width, Height

- Type

of Frames :- RF, CB1, Mono slope

- Design

Code= IS , AISC

- Wind

Velocity = IS 875 -1893 – Part3

- Seismic

zone = I, II, Iii, IV

- Collateral

Loads= Cabel tray, Pipe rake etc.

TYPES OF FRAMES USED IN BUILDING.

ADVANTAGES OF PEB

•

Lower cost: - due to the saving in design,

manufacturing and on site erection cost.

•

Minimizing time of construction

•

Quick Erection :- Easy to install & easy

to remove

•

Low Maintenance

•

Flexibility in Design

•

Scope for Future Expansion

Applications of PEB

•

Low rise industrial buildings

•

Ware houses

•

Power plants

•

Laboratories

•

Airport hangers

•

Parking lots

•

Factories etc.,

Thanks

Comments

Post a Comment